NEWS

Analysis of Thickness of Nickel Electroformed Nameplate

Writer:admin Time:2025-01-06 18:16 Browse:℃

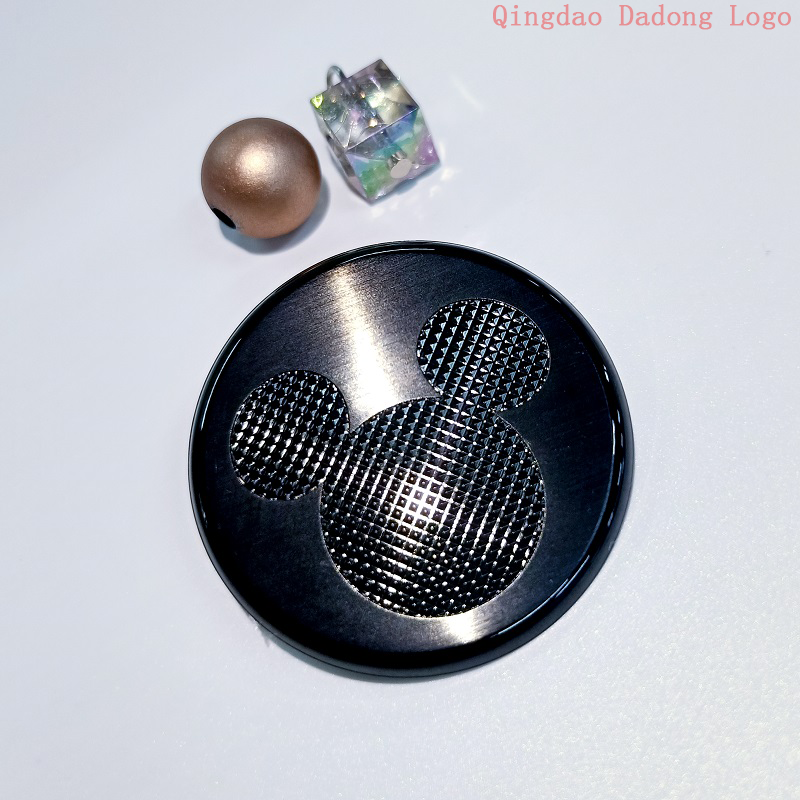

Nickel electroplated nameplates, as a high-precision and durable identification solution, have been widely used in multiple industries.

As one of the important indicators for measuring product quality and applicability, its thickness is crucial for ensuring the functionality, aesthetics, and durability of the nameplate.

Da Dong Electronics will delve into the relevant knowledge of nickel electroplating nameplate thickness to help you better understand this key parameter.

1、 The Importance of Thickness in Nickel Electroformed Nameplates

The thickness of nickel electroplated nameplates directly affects their physical properties, visual effects, and service life.

A suitable thickness can ensure that the nameplate has sufficient strength and wear resistance to withstand friction and scratches during daily use.

Meanwhile, thickness is also a key factor in controlling the weight, cost, and adaptability of nameplates to different installation environments.

In addition, thickness can also affect the glossiness and texture of the nameplate, thereby affecting its overall aesthetics.

2、 Common range of thickness for nickel electroplated nameplates

The thickness of nickel electroplated nameplates is usually determined based on specific application and design requirements.

Generally speaking, its thickness range can vary from ultra-thin (such as 0.03-0.08mm) to thicker (such as 2.5-3mm).

Here are some common application scenarios for thickness:

Ultra thin nameplate (0.03-0.15mm): This type of nameplate is usually used in applications with strict requirements for weight and thickness, such as electronic products, precision instruments, etc.

They are lightweight, smooth, and can tightly adhere to the surface of the product, providing clear information identification.

Standard thickness nameplate (0.15-0.3mm): This is the most common thickness range in nickel electroplated nameplates.

This type of nameplate has sufficient strength and wear resistance, and is suitable for most industrial and commercial environments.

They can withstand friction and scratching in daily use while maintaining clear information labeling.

Thicker nameplate (2.5-3mm): This type of nameplate is usually used in situations that require additional strength and durability, such as outdoor signage, mechanical equipment signage, etc.

A thicker nameplate can provide a better protective layer to prevent external environmental erosion of internal information.

3、 Factors affecting the thickness of nickel electroplated nameplates

The thickness of nickel electroplated nameplates is influenced by various factors, including:

Application requirements: Different application scenarios have different requirements for the thickness of the nameplate.

For example, in situations where greater pressure is required, the nameplate needs to have a thicker thickness to ensure its stability.

Material selection: The material selection of nickel electroplated nameplates also affects their thickness.

Different materials have different physical properties, so it is necessary to choose the appropriate material and its thickness according to specific needs.

Production process: Parameters such as current density, electrolyte composition, and temperature during the electroplating process can affect the thickness and quality of the nameplate.

Therefore, it is necessary to strictly control these parameters during the production process to ensure that the nameplate achieves the expected thickness and performance.

4、 Conclusion

The thickness of nickel electroplated nameplates is a complex and important parameter that directly affects the functionality, aesthetics, and durability of the nameplates.

When selecting and designing nickel electroplated nameplates, it is necessary to fully consider factors such as application requirements, material selection, and production processes to ensure that the nameplate achieves the best performance and effect.

By reasonably controlling the thickness of the nameplate, we can provide users with high-quality and durable identification solutions.

CATEGORIES

LATEST NEWS

CONTACT US

WhatsApp: +8617685841638

Tel: +8617685841638

Email: guanweiwei@dadonglogo.com

Addr: 7 Tonghe Road, Pingdu, Qingdao