NEWS

How Nickel Electroforming Manufacturers Solve Mass Customization Challenges

Writer:admin Time:2025-03-26 18:21 Browse:℃

As branding enters the era of personalized marketing, nickel electroforming innovators are turning "single-piece customization" into reality through flexible manufacturing revolutions.

A manufacturer's 3D-printed rapid mold technology slashed traditional mold costs by 80%, delivering prototypes within 24 hours from design files. For a trendy eyewear limited edition series, 500 unique temple logos with varying text combinations were completed from design to delivery in 5 days, setting an industry record.

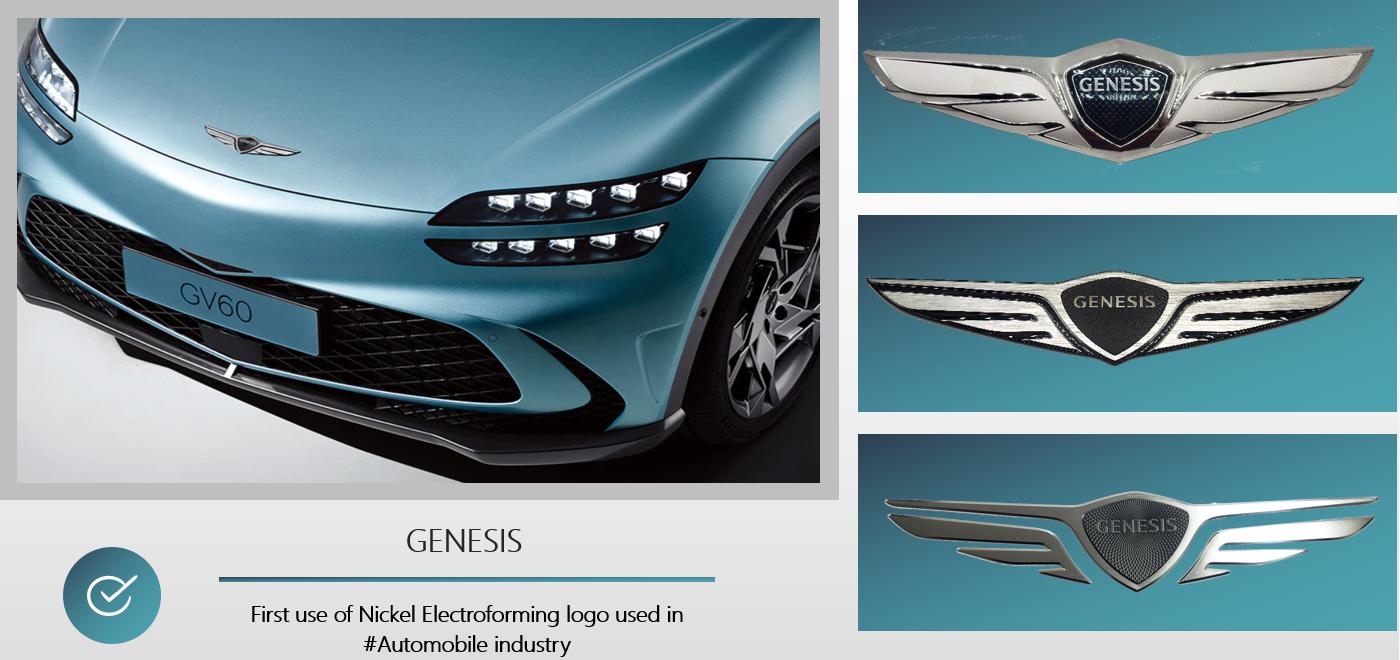

In mass production, digital dynamic parameter adjustment systems demonstrate unmatched efficiency. One factory produced 10,000 automotive logos with serial numbers, using AI algorithms to maintain <5μm clarity error across individual markings through real-time current density and solution flow optimization.

Disruptive cloud collaboration platforms allow designers to upload 3D models directly, receiving instant electroforming feasibility reports and cost-optimized process recommendations. A European furniture brand reduced cross-border communication costs by 60% through this platform while developing 200 custom drawer handles simultaneously.

CATEGORIES

LATEST NEWS

CONTACT US

WhatsApp: +8617685841638

Tel: +8617685841638

Email: guanweiwei@dadonglogo.com

Addr: 7 Tonghe Road, Pingdu, Qingdao